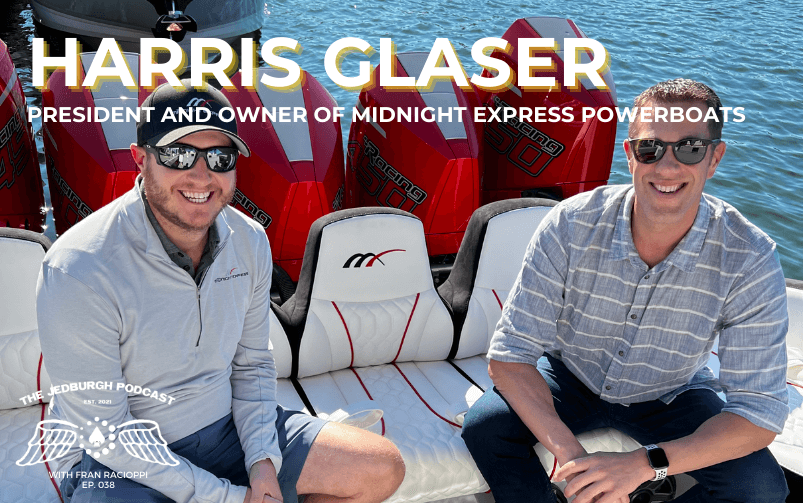

Midnight Express sets the standard as the leader in luxury center console powerboats. In this episode, Host Fran Racioppi travels to Miami to combine his passion for boats, journalism, and the beach as he sits down with Harris Glaser, President, and Owner of Midnight Express.

Harris, along with his brother Eric, bought Midnight Express in 2006 and have since redefined the boating industry bringing unparalleled design and construction, elaborate color schemes, flawless precision, and unmatched performance.

Fran and Harris discuss entrepreneurism, building an iconic brand, precision engineering, high-level customer experience, the importance of human capital, and the keys to building a successful family business. We also discuss the impact the loss of his father had on the company and his family; and how COVID has propelled the boating industry into uncharted seas.

—

[podcast_subscribe id=”554078″]

—

Precision and performance define the ultra-competitive luxury boating industry. At the top of the pack stands Midnight Express, the leader in center console powerboats. They say, “When your work is your passion, it’s not work at all.” For this episode, I went to Miami to meet Harris Glaser, President and Owner of Midnight Express, to combine my passion for boats, journalism and Miami Beach. Harris, along with his brother, Eric, built custom-powered boats capable of speeds near 100 miles per hour and comfortable in almost any sea condition. They purchased the company in 2006 and now own the standard for excellence in boating.

Harris showed me around the Midnight Express 43′ Solstice and then sat down with me in a Grammy-winning recording studio to discuss entrepreneurism, building an iconic brand, precision engineering, customer satisfaction, the importance of human capital and the keys to building and running a successful family business. We also discussed resiliency and adaptability as COVID has propelled the boating industry to new seas.

—

Harris, welcome to the show.

Thank you so much for having me.

We are here on location in Miami Beach, Miami, the boating capital of the world. It’s home to the million-dollar yachts, glamour, lifestyle of the rich and famous, Gianni Versace, Miami Vice, which I felt like now because I got to spend with you at the service center on the 43′ Solstice. This episode, for me is defining almost in my mind because I get to bring so much of my world together. Boating is something, like you, I have been involved in since I was a little kid. Since I was born, we have always had boats. I grew up on the water.

Journalism, I get to come down here and spend time with you to tell your story through our lens. Also, Miami is the place where you live now and where I lived when I was 10 to 15. It was the formative years of my life before the city totally blew up and became the metropolis that it is when there was nothing in Downtown Miami. To bring these things together here is such an impactful experience. I appreciate you taking time out of your busy schedule to sit here with me.

It’s my pleasure.

Before we get into your story and talk about the boats in Midnight Express, I almost have to caveat that we need the readers to go to your Instagram page, @MidnightExpressBoats. They have to go to the website, MidnightBoats.com and take a look at these machines so they can visualize everything we’re about to talk about.

Let’s start with the brand and company. We speak so much on this show about leadership development and mission statements. Midnight Express has a very simple mission statement. On your website, you say, “We have a simple mission statement. To build the best quality, highest-performing powerboats, utilizing cutting-edge technology combined with a groundbreaking design.” You called Midnight Express a high-performance, highly customizable day boat.

These boats are iconic. They are recognizable from a mile out on the water, as far as you can see. I can’t see that far but I can still see the Midnight Express when I see it. Everybody knows who these are. They pass you and it doesn’t matter what boat you’re on. You look at a Midnight Express and you say, “I wish I had that boat.” Talk about the brand, what it is and what it means to you.

My family acquired Midnight Express back in 2006. It was an ongoing company. It started in ’99 in its current form. Midnight Express did exist in the ’70s and ’80s as a boat company with a previous build and isn’t the same company as it is now.

Is it more fishing-focused?

No, it wasn’t back in the ’70s and ’80s. I won’t get into the story because I don’t know all the details on it but there was some nefarious act and business going on.

It’s South Florida in Miami in the ’80s. There’s a lot of money to be made and you got to move some stuff from one place to another really fast.

We’re far away from that but that’s where it started. Its current form started in ’99. In 2006, my family acquired the business. We have had it for many years. We have taken it. It had this great base of a company and we thought we could put our stamp on it. We have owned it for quite some time now and have seen the ebbs and flows of the economy and the boating industry.

Now, we’re at the highest point it has ever seen. Our brand, as you say, you can notice it from everywhere and I do appreciate that. I live on the water. At night, I can see the silhouette of the archtop of my boats and I say to my wife, “Is that Midnight? That’s a Midnight.” We’ll look out and squint and we’ll say, “Yes, that’s a Midnight.” That’s important to me that you see it and you know it’s a Midnight Express.

We speak many times with many of our guests about the impact and creating impact in society, world organizations, teams and individuals because we’re going to get into your story as an entrepreneur and your upbringing and then what drove you to do this. To wake up one day and say, “I’ll buy a boat company and become a boat manufacturer,” not too many people wake up and think about that. When you do something that an entire industry looks at and says, “That is the model. That is the standard. That is what we’re seeking to achieve,” it’s truly impactful.

One of the biggest elements of this boat and this company that sets you apart from everyone else is the customization aspect. These boats are made completely at the will and desire, almost with what the client wants. Can you speak about the customization and the construction process? It is a unique construction process that you’re using with these boats. Tell me a little bit about that. Also, what can the client do and what can’t they do?

I’ll start with the construction process. Our holes and decks are fully infused. Vacuum infusion is a technology and process in which we lay the layers of fiberglass dry and put a big bag over it. We suck the air out and infuse the resin in. That creates less resin waste and makes a stronger and lighter boat. A lighter boat now is more fuel-efficient and faster. While speed is not our primary concern, it is a concern that is something we look for. We want to be at the higher end of the speed in our center console performance class.

In terms of production, we use all of the highest quality materials that we can find. We do carbon fiber when we can and when it makes sense from a structural standpoint. It’s not only from a visual standpoint because carbon fiber is pretty to look at and sets it apart but it also has a structural component as well. We do use carbon fiber in a lot of places.

[bctt tweet=”It just changed people’s perspective that the boat doesn’t have to be white, it doesn’t have to be a blue hall side with a white deck or a white hall side with a white deck.” username=”talentwargroup”]

From there, it allows us the base. We customize the boat’s seating layouts, colors, motor options and electronics options. We have different hardtop options, moonroofs and no moonroofs. Clients come to us and say, “I want to shower at my hardtop.” We’re like, “Why would you want to shower on your hardtop outside?” They say, “I just want it.” We say, “Okay. We’ll figure it out.” You laugh but that is not sure what happened. Anything that’s not majorly structural, we’re happy to accommodate or maybe not happy but we will accommodate.

There’s a bit of a copycat mentality where a client will see a boat on our Instagram or website and they’ll say, “I need it to look just like that.” They’ll come in and say, “I want it like that but now let’s do it this way and move this here and add a second row. Could you get rid of one seat?” You’re like, “Okay, sure.” We’re able to adapt with most people and start with that base. As a client sees and feels it more, they are able to change what they want out of a boat. We can adapt the boat to be able to get what they want out of it.

It includes the paint colors. You have talked about matching paint colors to people’s cars.

Getting paint colors is almost a headache. Getting a client to choose the paint is quite difficult because we give almost unlimited options. The car world is a huge inspiration. We do a ton of Ferrari, Lamborghini and Porsche colors because they are great colors and easy to match. We do that a lot. On our website, we have got a full Boat Builder with a full-color wheel. You can choose out your options and at least have some level of visualization as to what your boat is going to look like. We were the first ones to do that on a boat. It’s one of our highest pages in terms of time spent beside the home page. It’s pretty wild how much time people do spend on that. It’s pretty cool. That gives you that visualization so that you can then come in with a better idea of what you’re looking for.

How long does that process take to go through the design phase with a client, get it all designed and then fabricated?

The design phase is up to the client. We got guys who will come in and within 1 to 2 hours, it’s done and sealed. They won’t think twice and they don’t change anything. That’s not the norm. Usually, it could take days or weeks for them to decide, “Do I like this silver or that silver? Should it have a red accent or no red accent?” That phase can take some time. We do have time constraints because if we don’t have all that information before we start the boat, we’re not lost but certain things need to be ordered ahead of time and certain colors. We try to make that as quick as possible. From the start of production on the water delivery, it’s anywhere from 5 to 6 months. We are with everybody else, dealing with supply constraints and labor constraints.

I watched an interview that you did at one of the boat shows. It was interesting because you said that people come to you because of the flare. One of the first boats you made in 2008, you painted black. We’re talking about an industry that, even now so many boats are white and you see them everywhere. All of a sudden, Midnight Express comes out with this black boat. I look at this boat and think about this customization. I’m a detail-oriented guy. I’m like, “Details matter because everything in here is so detailed.” Everybody went crazy when you came out with this new black boat. How did that change people’s perspective of what you can do with these things?

It changed people’s perspective that a boat doesn’t have to be white. It doesn’t have to be a blue hull side with a white deck or a white hull side with a white deck. That was our first one. It didn’t start picking on until a few years after that. It’s probably not until 2014 when it caught on. It took some time for our class to catch onto that. Between 2008 and 2014 was the downturn so fewer clients to begin with.

Once 2014 rolled around, I had another client who came in and he said, “You got to do all silver. Look at this Mercedes-Benz. Look the way they do these seats, Harris. Let’s do the seats like this. Even though we’re painting it a Porsche color, let’s do everything that color.” We’re like, “Yes, sure. We can do that. That sounds fine.” As soon as that boat came out, it sparked our clients. I still believe it’s a hallmark of what we build. We rarely build white gel-coat boats. They are almost always full paint and that’s what epitomizes Midnight Express’ design at the moment.

How many lines of boats are available?

I make the 34′, 37′, 39′, 43′ and 60′. We are about to put our first 52′ on the water. We haven’t marketed and told anybody. We have a bunch sold to our existing clients. We haven’t put it on our website. We have done nothing for it in terms of letting anyone know, except for our existing clients already. It will be awesome. This is the first time I have ever talked about it outside of our existing clients. We’ll have that in the water soon and that is going to be a spectacular boat. I’m super excited about it.

Marketing is something that you haven’t had to do a whole lot about. The visualization itself brings clients.

Early on, we were doing a lot of traditional advertising in the traditional magazine publications out there. They got wildly expensive and we weren’t seeing many calls from it. Social media has been huge for being able to market the boats without having to spend money. We don’t boost posts. We don’t do anything. Our Instagram following has naturally evolved to where it is and we have hundreds of thousands of followers. It’s a lot now. We get millions of views on some of these videos and stuff.

It has been great and it’s all organic, which is more impactful than boosting views. You can do that and that’s great and that works for a lot of people. I don’t think that works for a brand like mine in such a niche brand. For every 100 people I hit, 99.99 don’t have interest in it. We don’t throw many marketing dollars out there but social media has been very impactful.

I listened to a podcast, a Miami guy who is a big Miami person. He was saying how social media for him has been massive. Even though I knew it was big for us, it hit home even more when he said it. His Miami brands are huge. It hit home that social media is free. We’re all attached to it and obsessed with it. It’s easy to go reach hundreds of thousands or millions of people within seconds.

As long as you have good content, you got to have good content.

Content is super important. We have a full-time videographer and photographer. We always talk about creating new content. That’s hard too sometimes. I have got thousands of videos of a boat going through the wall and that’s great. Everybody is a little different. It’s beautiful and all these things but how do we make it now different? What is going to make that video pop so that this guy is not like, “You did this 27 times. Thanks for the 28th?” Show the boat but show a difference. Those are the things we talk about internally and it’s hard but we do try. We do helicopter shoots, drone shoots and anything we can think of to create content that helps our brand.

Let’s talk about speed and the engines. The boats are beautiful, the craftsmanship, the manufacturing piece but there’s a workhorse in this thing and that is its engines.

[bctt tweet=”Social media has been huge for being able to market the boats without having to spend money.” username=”talentwargroup”]

We are Mercury-exclusive. We have been for a few years. Ninety-five percent of our boats out the door are with Mercury Racing, 450-horsepower motors, anywhere 3, 4, 5 or 6 motors on the back.

What changes when you go from 2 to 4 to 6?

The size of the boat changes too. We had a client who put four on our smallest boat on our 34-foot boat.

How fast?

I won’t even say how fast it was because it was crazy. It’s way too fast. It’s triple digits and not necessary. That’s overkill. Our 34′ twins are triples. Our 37′ triples are quads. Our 43′ quads are quints. Our 52′ and 60′ are quints or six topples. Speeds go from on the low end and 70 is probably the low end of a boat that I have now that I would build. The high end is that mid-90, 92, 93 or 94 miles an hour. We’re able to play with full carbon fiber builds and cleaver props and reach that 97, 98 or 99 range on a lightweight carbon fiber 43′.

It’s fast on the water. Don’t forget that this is a center console boat with a hardtop and an arch and all the accouterment of a luxury boat. It’s not just one of these catamaran or go-fast boats where they are meant to go 120 to 180. We’re doing near 100. It’s not a speed boat or race boat. It does go fast. To put it in perspective, it’s like a fast SUV.

How many are you building in a year?

We’re building about 40 boats a year. It’s constrained more by the supply and the labor as opposed to demand. The demand is quite high. We are constrained at the moment.

What makes them so good in rough water? You talked a little bit about the construction and then there’s this thing called the double-stepped hull, which I’m interested in. I’ll say the conversation versus negotiation versus argument that I had consistently with my wife when we got on our boat, which is it’s too rough. I’m like, “You’re in the ocean. How can it not be too rough?” Can you talk a bit about the rough water, the construction of the boat and how that works?

Our boats are designed to be open-ocean, rough-water-going boats. With that said, there’s always a limitation. At a certain point, the waves are large, especially for a 40-foot boat. We designed the boats knowing that they are going to be in the ocean and that our clients sometimes got to get there. Maybe they weren’t planning to go out in that kind of sea state but they are there. It can change very quickly. Our boats are all over the world. The lion’s share is here in South Florida and The Bahamas. They travel back and forth. That’s one of the luxuries of living in South Florida with a boat like ours. You can be in Bimini in 45 minutes. You can be in Nassau in 3 to 4 hours. You can be in the Exuma in 4 to 5.

You have multiple engines. It’s your risk factor of getting stuck out there as well.

You always want to be careful with that stuff. You carry a sat phone if you’re out in the middle of the ocean because your cell phone doesn’t work. Carry an EPIRB, which is a homing beacon that connects to the coast guard. There are certain safety precautions that you should take when you’re out there. Our boats sometimes get stuck in a sea state that’s bigger than you intended. You have got to get home and you want to go home comfortably. You want to get home fast. You don’t want to be going 5 miles an hour. You want to be going 20, 30 or 40. Some of our clients sometimes don’t realize you go 7 miles an hour in a huge sea. It’s more uncomfortable than if you were going a little faster.

I tried to tell this to my wife.

They don’t want to hear it because it doesn’t feel natural but that is true and that is the case. It’s a long-winded answer of saying, yes, we build boats very strong to be out in sea states.

What about cost? What is the average price? What is the most expensive?

On the low end, it would be on the $450,000 side for our 34′. Our 37’s are $600,000 to $900,000. Our 43’s are $1 million to $1.4 million. Our 52’s are about $2 million and our 60’s are about $3 million. Get a big piggy bank and keep saving. They are expensive to build. The man-hours that go into each boat are high. I wish I could and build more but I don’t stamp them out because they are customized. My guys are always adapting to each boat so they can’t get in that real rhythm of building of repeatability.

You have made many of these for the government, the Coast Guard, Department of Homeland Security, Customs and Border Patrol. Is there a big difference in those boats minus the fabrication of some mount for a 50 cal. or something like that?

We did not change the way we built a boat between a government contract and a civilian. We haven’t built a boat for the government in a few years. We built Coast Guard boats, Navy boats and a lot of Customs and Border Protection boats. As time has evolved and as the government has become more concerned about longevity for their operators, it has become more thought into how the boat is built. Originally, they would take seized boats and those were the boats they used.

[bctt tweet=”Role clarity in a family business is so important. Role clarity in the building of any business is important.” username=”talentwargroup”]

This has been going on for many years where they are like, “We need longevity for our operators. It’s rough out in the ocean.” They can’t say, “It’s rough. Let’s not go after the bad guys.” It’s not an option. Shock-mitigating seats, wind protection, sun protection and ergonomics were big things that we were testing with them and trying to make better. We would meet with the operators mostly from CBP and decide, “With the Midnight you have now, what is your biggest problem?” “I have got a belt full of gear.” They have got their vests, multiple guns, handcuffs and all of their stuff.

They are in the sea. They have got to get out and maneuver around the boat maybe fast. Maybe it’s 8 or 20-foot seas. They have got to move around and they need to be able to move. Anything that you can get stuck on, take it away. Don’t let it be able so that a shirt or vest could get hooked. It’s moving controls to certain places, moving the windshield close or making a windshield taller. There are a million different, little tiny things that make a difference to them.

I was always proud of how we did that for them. The government has moved on from fiberglass boats into aluminum boats. The main reason is the cost difference. It is pretty easy to find welders and someone to fix an aluminum boat. Fiberglass, to an extent is an art. Fixing fiberglass in gelcoat is an art form. Finding those artisans is getting harder, especially for the government.

Let’s talk about business and entrepreneurism. You mentioned you purchased the company in 2006. You grew up around boats but you weren’t a Miami guy. You’re from Baltimore. Your dad and your brother come together. You went to Babson. Your brother went to BU and studied Engineering. We’ll have to meet him because I haven’t had a chance because we overlapped. Possibly, we were in the same year and I had a lot of friends in Engineering. He probably made the better choice going into Engineering.

It has taken me many years to get back to what I studied in Broadcast Journalism with a little detour going into Special Operations, which I love and was formative for me. It was funny to learn that he was there when I was studying Engineering and he has gone off to do this. It’s a small world. I may have told you this. I was accepted to Babson as well and my decision was between Babson and BU. I went to BU because Babson was about 2 miles closer to my house than BU was. Either way, I was going to school with one of you.

Babson is so small. I would have known you there for sure. We have 40 to 50 kids in our class.

I had 130 in my high school, which was only about 4 miles the next town over from Babson. That’s why I was like, “I can’t go to Babson because it’s about the same size as my high school and it’s right down the street.” Talk about why you jumped into boating. You went to school, you get out and now it’s like, “I got to figure out what I’m going to do.” You studied Entrepreneurism. How do you decide to go look for and acquire a boat manufacturing company?

My brother worked for another boat manufacturer down here for a few years after he graduated from BU and loved it. I don’t know that we always thought we were going to do a family business. My father was an ophthalmologist, a retina surgeon. Both my brother and I had decided we were not going to be medical professionals. We decided that pretty early on. My brother was down here working for this other company and he was enjoying it.

My brother is unbelievably smart. He wanted to have his own stamp and build his own thing. The easiest way to do that was to acquire a company that had some start rather than starting truly from scratch. My father was able to do that with us. I’m not sure I ever thought I was going to be in the boating business. Growing up, we were on boats all the time on the Chesapeake Bay. We loved being out there. We spent all summer on the bay at Downtown Annapolis and we loved it. When you think about it years ago, it fits naturally.

Going to college, for me, Babson is in entrepreneurship. That’s not all they do. It’s the number one in entrepreneurship for 25 years or whatever it has been. It’s amazing and it’s a great school. It’s a bit of an alternative learning style where it’s very interactive. I can’t say I knew I wanted to be in boating and certainly, not manufacturing because I had no manufacturing background my brother had started but it fit nicely.

When we started, my brother was on the manufacturing side and I was on the sales, marketing and finance side. We still are that way many years later. My brother can do my job and I can’t do my brother’s job because I’m not an engineer. However, I understand how the manufacturer is about and what I’m looking at. I can assist when necessary. We have very complementary skill sets.

That’s important in a family business. I’m thinking about a couple of conversations we have had and we spoke with Mitzi Perdue. Her husband was Frank Perdue. Perdue Chicken is a family business and still is to this day. Her father was Ernest Henderson, the Founder of Sheraton Hotels, which stayed in their family for a very long time and before they exited to Marriott.

Role clarity in the building of any business is important. Seth Goldman is another entrepreneur that we have spoken with. Seth was the Founder of Honest Tea. He is also the Chairman of the Board at Beyond Meat. Now, he started a company called Eat The Change and PLNT Burger. He has been very clear on the differentiation of roles. If you have two founders or multiple founders but their roles are complementary then you can have success as long as everybody clearly understands.

Mitzi Perdue is very big on, “You don’t air your dirty laundry,” in family business because inherently within the family business, there becomes some friction at times. Your dad was instrumental at the beginning of the business and unfortunately has since passed. Can you talk a bit about the dynamics within the business between your brother and the family piece? How do you approach the relationship? How has that grown over the years?

My brother is an engineer. I have a business background. We are complementary, to begin with. My father owned his own practice. He was a business person on top of being a medical doctor. We were in the business down here locally in Florida and he was up in Baltimore still. There were lots of phone calls and visits. My father was very good at helping foster my brother and I’s leadership roles. I was 21 in change when I got down here and my brother was then 25. He had some experience but he was young. Now looking back, we were babies.

We’re still buttheads but we know the other’s expertise. If someone strongly believes one thing versus another, let’s say it’s A and B. I believe in A and my brother believes in B. If I’m adamant about it then he’ll say, “If you’re adamant then that’s what we’ll do.” It’s the same back the other way. If he is super adamant about something, I back off and say, “If that’s what you want, that’s what you want. I have said my piece and that’s it.”

We have worked well together for many years and we’re more successful now than we have ever been. We’re doing something right. It’s working. I don’t think there’s any one master plan for family businesses because everyone’s personality is different. Communication is key to even having a hint of hope to making it successful. I believe sometimes you got to give. It took me time to learn that on the customer side too. Maybe I’m right but you give it to them anyway. Make them happy.

We talked about humility. We use the term humility. We have tied a lot of our conversations to the nine characteristics of elite performance as used and defined by Special Operations Command. What do you use to recruit, assess and select high potential and high caliber talent? Those are drive, resiliency, adaptability, humility, integrity, curiosity, team ability, effective intelligence and emotional strength. What you’re talking about in terms of this is this humility piece.

[bctt tweet=”Communication is key to even having a hint of hope to making it successful.” username=”talentwargroup”]

It’s funny because I worked for my mom for about four months. I quit and was fired about six times in a very short amount of time. Sometimes often on the same day, both of those would occur. I have also done work with my brother. We have gotten along great and advanced the company and done some amazing things together. It does take that element of humility to say like, “Maybe I’m not always right. I got to accept that the other person is probably right.”

You’re not always right. As the leader of a business, you always hear super successful people say, “Find people smarter than you and let them run.” There’s got to be that element of finding other people that you can rely on and let them make the decisions. Even in a small business like ours, it took me time to learn humility, as you put it. When I was 22, humility wasn’t oozing out of my veins.

Even when you’re right sometimes you give anyways. You know you’re right. You have the proof you’re right but sometimes it’s cheaper, easier and faster. It’s one of a hundred things to give. That’s not saying you always have to give but sometimes it’s the right thing to do. That can be within your partnership, with your clients, B2B with your partners from that side or at home with the family. That’s an important piece that I have learned later in my career. That has been more prevalent as of late.

We tie that to what we call effective intelligence. The aggregate of your experiences of the past as you gain experiences and maturity, you get older. You take all those experiences that you had. Now, that frames your perspective and how you make decisions in the future. Now, you can say, “I may not have encountered this before but I experienced a few things like this in the past. Now, I can make a better decision than I would have made when I was 22.” Outside of you and your brother, there are over 120 employees in the company. What are some of the other critical roles that sit within the organization?

Our head of production is the next-most important role. Our clients come in to see the boat to be built, not all of them because we have clients all over the world. Sometimes they’ll either hire a firm to come in to check up on the build or sometimes, they won’t come in at all. Usually, clients come in during the build process. They see the guys out working in the manufacturing facility. It is high-touch with the clients. That client touch is more for myself, my brother, our salespeople and our service team. Service is super important and a tough job. Rarely does he get phone calls, where it’s like, “Chris, thanks so much.” The service manager is a tough role. They are usually calling because they have a problem, not because everything is hunky-dory.

“Your boat is broken and your part will be here in six months.”

That’s not what these guys want to hear for sure. We try our best to alleviate. There’s got to be the most important things. If your boat is inoperable, a motor is down or something that will hinder you from going out on the boat, that’s a priority. If you have got a scratch and that’s all it is, your scratch is unfortunately not going to take priority. You can still use your boat and operate your boat. It just happens to have a scratch on it. We have no choice but then when that same person has a motor problem and I jump, they don’t want to get it but they get it because all my clients are very smart people.

One of the cool parts about the whole value proposition of Midnight Express is this quote that you have, “When you purchase a custom Midnight Express, you become part of the Midnight family and have full access to the owners, which is an extension of the hardworking, skilled tradesmen and women who build every part of your boat.”

You have also talked about availability and accessibility. You have tied that to some of the success of the company in this relationship with the clients. That makes me think of integrity as a big word, which is one of those nine. You see that when you look at these boats. When you invite people onto the production floor, it’s like, “We have got nothing to hide here. You’re going to see this thing from the ground up,” which I can imagine as the owner you got to tell that story.

When we give our plant tours, you start at the beginning with the molds and how we build the fiberglass. You move your way through proper paint, rigging, hanging the engines and into the final sea test. That’s super important. Seeing your boat come alive is different. Even with high-end cars, you rarely get the opportunity to see your car be built or see even one of the cars be built. It is a little unique. We are open. If you want to come to see your boat, come on. A little phone call ahead of time is nice but sometimes they don’t.

If it’s not my client and it’s one of my salespeople’s clients then they’ll show them around. We all work together. I give my cell phone out to all my clients if they want it. If they don’t want it, they don’t have to have it. I like to know and try to help the best I can. Maybe I can’t fix your issue over the phone or maybe I can but at least they hear you acknowledging like, “This is an issue. What do I do? How do I fix it? What is wrong? Saturday, Sunday or whatever it is?” We have created friendships with clients.

A big reason we have been successful is the repeat clients. I don’t have a stat for you but we have an unbelievably high repeat rate. My clients come back and buy again. That has been unbelievably successful. I also think it’s a testament to how we run our business and how our boats look to everything to the service side. You can’t make everyone happy. We try our hardest but it’s impossible to make everyone happy. Giving them access to me for me to take three minutes out of a Saturday is fine. If I can’t answer, I can’t answer and then I’ll call back 1 or 2 hours later when I can answer. I don’t duck phone calls.

We all do that as a partnership. It’s a long-term relationship. It’s less transactional. You buy something like this and this requires a partnership between you and the client. It’s going to be in there for maintenance and all other reasons that you’re going to want to create that community.

The community base is an interesting thing that we have started doing as these rendezvous. It’s where we get our clients together on their boats the first time we went to Bimini a couple of years ago. In 2020, we went to the Duck Key. It’s down about an hour and a half South of here. That has been great at building a community, not only between us and our clients but our clients amongst each other. They are all our clients. I don’t want to say they are all the same. They are like-minded people. They are all highly successful business owners. I have very few corporate guys. It’s mostly business people who own their own businesses. They all love the same boats, cars and toys. It’s an easy transition and a lot of them have become friendly with each other.

The community is important but there’s also the cultural aspect. You have built a culture within this company. Can you talk a bit about how you think about that? You have had to lead and grow this organization and you built this community amongst the owners themselves. Internally within the company, when you think about the pride and prestige, how do you get everybody there to buy into that?

That’s hard and then we do have a lot of turnover in employees. It’s a bit of a high turnover state. We try our best to let the people when they finish their job, there’s something tangible there. There is a bit of pride. When you lay up a hull 8 to 10 days later, you take the crane and it pulls it out of the mold. You can see what you made from ten drums of resin. You now see what you have made. It’s nice to be able for the guys to have a bit of a tangible product to touch. That’s at every department. They all can see the job that they did as it comes out of the mold or as it’s painted, put together and assembled. That’s important for them that they are making a high-quality product.

We talked about ownership a lot as an employee and a member of an organization. I’m bought into, “I embrace and accept my role and contribution to the organization. I’m proud of that. Therefore, I go after it.” When I was with you, we saw the maintenance technician in the well of the boat under the rear seats. There was no complaining. There was no, “This is all messed up.” It was like, “Here’s the problem. I have got it stated and here is the resolution.”

That’s hard but it’s having the manufacturing have some ownership in what they do. Also, I make mistakes. Everybody makes mistakes. I’m okay if you make a mistake. I have no problem. If you make a mistake, tell me you made a mistake and we move right on within sixteen seconds. When you hide a mistake and then point the finger and say, “It wasn’t me. I didn’t do that. That was Jim next to me,” that’s when it’s like, “We have never fired anyone for making a mistake. You lied to me and told me it wasn’t you. I looked at the camera and it was you.” That’s when we have problems.

[bctt tweet=”Everybody makes mistakes. If you make a mistake, tell me you made a mistake and we move right on within 16 seconds.” username=”talentwargroup”]

I don’t think making mistakes is bad, even when it’s a tangible mistake that can cost me money. I don’t encourage it but it’s okay and it happens. Maybe it cost me a couple of thousand dollars but that’s okay. “I made this mistake. I’m sorry. I know what I did wrong. It won’t happen again.” “It’s great you owned your mistake. Let’s move on.” I try to do that too because I know it’s important. That’s a hard thing to instill in people.

Every entrepreneur’s story has setbacks. You encountered a couple shortly after you bought the business. One was the 2008 financial crisis, which affected a luxury good like this. Also, in 2009, I believe your father suffered a motorcycle accident. Can you talk a little bit about those and how you weathered them? I think here about resiliency and adaptability. You’re sitting here and we don’t know as leaders.

We did an episode with General Stan McChrystal and it’s about risk. It’s episode 34. It’s about how do you, as a leader, detect, assess, respond and learn from risk because it exists in everything that we do. Your ability to understand it and then react in a meaningful way is what separates great resilient organizations from those that fail to act and inevitably fail themselves.

For us, the risk is more financial than anything else when we come out with a new model or it could be a bunch of things. The risk has been big. In terms of adaptability, our father was in an accident in 2009. He became paralyzed from a motorcycle accident. There were the two of us. There was my brother, me and my mother was out there.

I was able to travel. I was on 3 to 4 planes a week, going from Florida to Atlanta at his rehabilitation center to Baltimore because he had a business as well. It’s not that I could tap in and start the surgery but at least be there and do whatever it is that I could do to help the family. I was able to do that for quite some time and then have my brother still be here on the ground.

The 2008 financial crisis didn’t hit us until 2010. We had a government contract that was able to keep a great 2008 into 2009 but in 2010, when the government contract ran out, there weren’t many civilian boats to be built. We weathered the storm. It’s about cutting back when you need to cut back. We had to get bare bones. You don’t like to do it. No one enjoys that. We came stronger out of it.

Even when COVID hit, I instantly thought it was back to 2008, “Bootstrap and buckle up. Let’s clench up and figure out how we’re going to weather this storm.” The opposite happened. Boating has blown up. We saw that coming. COVID started in the United States in mid-March 2020. From the beginning of May to the middle of May, we started seeing, “I need a boat. I need to get out of the house.” We were like, “That’s interesting. We have some boats. Here’s one and we’ll send you this one.”

We still had our new boats were being built. I had zero cancellations. I had one guy pushed back about 6 to 8 months but I had nobody cancel an order. We were fortunate from that. I know everyone wanted to be outside. That was a great way to be outside, have fun, be contained and also be able to go to different places. It’s a unique mode of transportation. It’s outside so everyone felt super safe in doing it. It has been a skyrocket for our entire industry now.

I was talking to the service manager where I brought our boat down here for the week. I was telling the service manager where we’re storing it. He told me that there were 180 people on the waiting list. About 70% of them have new boats and they have nowhere to put them.

Marinas in dockage are probably going to be the next problem that our industry faces in terms of boats that are 50 feet and under where you want to keep them out of the water. Down here in South Florida, you can’t build a marina anywhere. There’s very little land on the water. There are some that are going up but they are few and far between. They are highly sought-after.

What about the COVID implications on the supply chain?

It’s tough. Every day is something new. You find a solution for one and then you have another problem and a different problem. I could go on for hours about supply chains. For our raw materials, we use resin and fiberglass. The polymers and resin are made at two different factories in the Gulf of Mexico. Some storm came through and knocked out the power to some factory. This was what my supplier was telling me. Now, this polymer that goes in resin couldn’t get it anymore. The resin can barely get it.

I have been with the same manufacturer for the better part of 12 or 13 years. He was like, “Harris, we’re going to supply you with what we need to supply you with.” I’m not building 1,000 boats a year because those guys, no matter what, weren’t able to get the volume. It has been difficult. We found our way around without having to sacrifice any quality of anything.

Mercury Marine has the motors. They have their own issues with giving us. We got put on allocation from them. We used to be able to ask for motors and they would give them within six weeks. Now, it’s eighteen months for them. If you place an order with Mercury Marine, it’s eighteen months. It’s difficult out there but we have been in business for a while and we have made our relationships. We don’t flip-flop our supply chain suppliers.

You’re not putting them against each other.

We tend not to say, “You were $0.10 cheaper. Let’s move over to you.” It’s not to say we like the price increases. We are fair with them and they are fair with us. That’s paying dividends now.

What is next?

The 52′ is our next model took to come out. We’re going to keep tweaking our existing models. Our next model to tweak will be the 34′. Even though it’s not our most popular model, we’re going to tweak it to make it more popular. From there, we filled our little gaps in and now it’s thinking about, “Where is our little niche of an industry going to go in the next 4 to 6 years?” Normally, that’s 3 to 5. Three years isn’t far away enough for anything to change, given the supply constraints.

When you think about what happened, we’re two years from the start of COVID. As painful as it has been and as slow as it seems at times, I can’t believe it has been two years.

For us, it’s to finish the 52′ and then see where else we can enhance our model lineup, listen to the customers and see what the customers want. They are going to tell us, “Harris, make a bigger cabin. I would love to see X, Y, Z in this boat.” We’re small enough that we’re able to pivot and adapt.

As we close out, the Jedburghs had to do three things every day to be successful. They had to shoot, move and communicate. These were the core foundational tasks. If they were proficient at a very high level at these core foundational tasks, their effort and focus could be on other challenges that came their way. What are the three things that you do every day to be successful in your world?

I’m going to be honest. I’m pretty micro-focused at the moment. With our supply constraints, it feels like you’re in the weeds. I do like to communicate. I do it with my wife, my brother and our management team. I do believe that’s unbelievably important. Showing gratitude to people whether that’s a waiter, waitress, your own employees or a customer, a thank you and a please goes a mile and a half. It always bothers me when people push their way. I say thank you as much as humanly possible and I always say please if I want something. I truly believe that you have got to go through your day respectfully and respect other people. That would be my second one and now I need a third.

I like your first one because micro was your first one. I got to give that to you. As leaders so many times, we think, “We need to think strategically. We need to think big picture. We don’t need to be in the weeds. We got to empower others.” All of that is true. One of the defining features between good leaders and great leaders is great leaders know when they have to go with what we call the point of friction or the point of action where they can be most impactful.

Since I have been with you, I have seen you take at least seven phone calls. These phone calls are tactical in nature. You’re talking about moving boats and parts. Even though your role is sales marketing strategy, you have identified that at this point in time, the place where you need to be to create the most impact and lead the company forward is in some of this micro-stuff that has to occur. I got to give you that one. I know you said it and you didn’t mean to like 1 of the 3 but honestly, that’s a big one. That’s something that we haven’t had in any of our guests yet of the ability to know, “When do I need to jump in and get small when I’m the big picture person?”

I do that often. That’s why we’re successful too. I’m at the factory every day. I walk in back probably 15 to 20 times a day. I make a loop around my factory because I might catch something that either they need to do differently or isn’t right because every boat is custom. Maybe we got confused with this boat versus that boat. That happens a lot unfortunately with customization. I walk around consistently and try to look at everything. I talk to everybody. I talk to every person in my office and management team twenty times a day. When you look at my call log, it’s to my managers and salespeople. It’s 50 calls a day.

My clients require answers, “When is my boat going to be done? When will this be fixed? What is going on with Mercury? What is going on with Garmin? What is happening?” I need to talk to my guys to know the answer from Mercury, Garmin or whomever or just our own problems. I need to know what that is so that I can speak knowledgeably about it to my clients. Maybe I can fix it, make a call or have a better idea or a different idea. Me knowing allows me to then maybe free up their day a little bit more so that they are not in the weeds and they can say, “Harris took care of Mercury. I can now go on to the next project.”

We spoke about the nine characteristics of elite performance as defined by the Special Operations Forces, drive, resiliency, adaptability, humility, integrity, curiosity, team ability, effective intelligence and emotional strength. The greatest leaders exhibit all of these. At different times, some are weighted higher than others but you exhibit them all. At the end of this, I always think about one when I think about my guest and their contribution and the impact that they have had.

For you and Midnight Express, I think about integrity. It’s this idea that we understand what is right. There’s honesty and openness. I look at the Midnight Express powerboats. I have gotten to know you and I think about excellence, precision and craftsmanship. It’s this level of performance that everybody looks at and they say, “That’s right. That’s how you do it. That’s the standard in this industry.” It’s impressive to see and I’m appreciative to have spent so much time with you.

The good news is that my wife is on board with getting one of these boats. The negotiation is between the 37′ and the 43′. We have to wait a little bit of time but what I’ll tell you is that you need to save the name, The Jedburgh. You have to start thinking about gray, black and yellow. I will be envious of every one of these Midnight Expresses that I see until I take possession of this boat one day, which will have the winged Jedburgh logo across the side and embroidered in the seats. That’s my goal.

I appreciate it. Thank you.

I want to share a quote from you right as we close out because it’s important to sum up your story. You said, “There’s no such thing as too young or too old. Entrepreneurship is a way of life. It’s about living, breathing and being your business. It’s the first thing you think about when you wake up and the last thing you think about when you go to sleep but it’s yours. You have the power to control your own destiny. Entrepreneurship is controlled chaos. It’s always changing but always in the direction you choose.” You have taken this company in a direction that we are all following. It was impactful and amazing to spend the day with you. Thank you so much.

I appreciate it. Thank you so much for having me.